Heating and cooling – when done right – is the MVP of a zero energy building. Space heating and cooling represent about 41% of the average commercial building’s energy consumption, making how we heat and cool our building one of the most important decisions in a zero energy project. Getting this step right is critical.

The HVAC system at the Climate Innovation Center has five different components that maximize the system’s efficiency: a variable refrigerant flow (VRF) heat pump system, a dedicated outdoor system (DOAS) with evaporative cooling, an energy recovery ventilator (ERV), ceiling fans, and passive natural ventilation mode.

Key Considerations FOR HVAC AND COMMISSIONING

All Electric VRF System – As an all-electric building, a VRF heat-recovery HVAC system is the heart of our approach to providing heating and cooling without using gas combustion. A VRF mechanical system (also called variable refrigerant volume or VRV) is an HVAC heat pump technology that optimizes the use of refrigerant during a heating or cooling period. We selected a highly efficient system that can flexibly provide heating and cooling throughout the building when deemed necessary.

We worked with the mechanical engineer to correctly size the VRF system, which required the engineer to account for the lower heating/cooling demand thanks to our building’s high performance building envelope. Leveraging the building’s enhanced energy efficient design and the heat-recovery technology within the VRF system, we were able to optimize the system to its ideal equipment sizing, steering clear of excessive capacity that could lead to unnecessary wear-and-tear, excessive operational costs, and risk the system’s longevity.

The VRF system has two heat recovery units that can use refrigerant to capture hot or cold air from one area of the building and transfer it to another portion of the building that needs it. A traditional cooling system would inefficiently reject and redirect this heated or cooled air to the outside through condensing units.

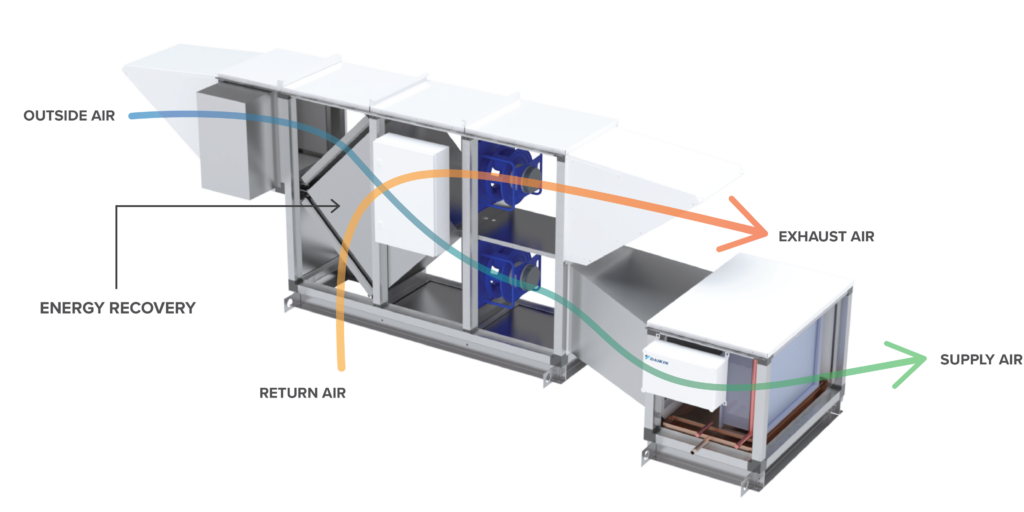

The Climate Innovation Center’s dedicated outdoor air system (DOAS) provides fresh air while the windows are closed and creates a slight pressurization to keep air pollutants out of the building. One innovative function of the DOAS is that it transfers energy from the building’s exhaust air into the outside air being brought in via an energy recovery ventilation (ERV) system. This pretreats the incoming air to reduce the amount of heating / cooling (aka energy) required to bring the incoming air to the desired temperature. In addition, to further reduce summertime electricity demand, we incorporated a highly effective direct evaporative section into the DOAS to pre-cool the air entering the building. For cold winter days, our DOAS includes a small refrigerant coil that assists with pre-heating when outside temperatures are very low. These solutions dramatically reduce the electricity needed to provide optimal ventilation. According to the U.S. Department of Energy, DOAS systems can improve the performance of an HVAC system by up to 30%.

In high occupancy buildings, a ventilation system is needed to bring in fresh air and exhaust stale air out of the building. The challenge with ventilation is that when conditioned air is exhausted, it wastes the energy that was previously use to heat or cool the air. When ventilating the Climate Innovation Center, our goal is to not waste energy used to heat or cool the air in our building when that air is exhausted. To optimize our HVAC system efficiency, our ERV pre-conditions the fresh air as it comes into the building using the energy captured from the exhausted air as it leaves the building. This reduces the amount of energy needed to heat or cool our building.

A natural ventilation mode helps a building save energy, but it also increases comfort and allow for fresh air. When the temperature is optimal in the spring or fall, we don’t want to use energy to heat or cool the building. We would rather open the windows and use fresh air. We made a point to include a natural ventilation option wherein staff at the Climate Innovation Center can place the VRF into ‘standby’ mode, open the windows, and turn on the ceiling fans. A signal near each thermostat indicates when the conditions are right for natural ventilation.

It may seem like a minor inclusion, but within the busy operating of a commercial building, a natural ventilation stage will provide fresh air to occupants using almost no energy when the humidity and temperature outside are just right. The ceiling fans in the workstation areas serve to support employee comfort with a higher temperature set-point in summertime.

This is not a piece of technology, but a process. We hired a commissioning agent to work with the mechanical engineer and contractors to ensure that the HVAC system will operate as it is designed. You would think that a mechanical system should run as it is supposed to, but these are complex systems with a variety of factors that affect their performance.

The commissioning agent monitors the system from design, through construction, and into the occupancy of the building. The commissioning agent is responsible for optimizing the building’s various systems by looking over the details of each of them. Importantly, when the UCE staff moves in, the commissioning agent ensures that the HVAC system is already working by coordinating the HVAC subcontractors and performing functional tests. This helps ensure that the HVAC system performs as it was designed, which is an important part of meeting our zero energy goals.

In addition to selecting high performance HVAC equipment, it’s important to ensure that the equipment is scheduled to operate in the most efficient way. We’re using controls that allow our unique system to conveniently switch between compressor-based cooling, DOAS evaporative stage, and natural ventilation modes for cooling. We’re also setting a schedule and set points that strikes a balance between minimizing operating costs, occupant comfort, and achieving our zero energy target.

Building Team for Step 5