Embodied carbon refers to hidden emissions that come from the extraction, manufacturing, and transportation of a wide range of building materials. These emissions add up, accounting for 11% of global greenhouse gas emissions. The Climate Innovation Center reduced embodied carbon emissions at every turn, opting for material choices with the lowest possible impact.

Key Considerations

Retrofitting an existing building emits 50 to 75 percent less carbon than constructing the same building from scratch. We purchased this 1951 building and worked with our team of architects, commissioning agents, and construction professionals to identify which aspects of the existing building we could reuse.

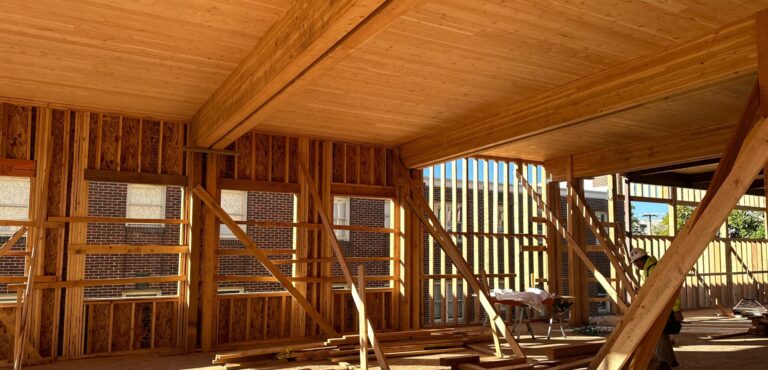

By reusing components from the existing building, we were able to avoid wasting the carbon emissions embodied in the original building materials. We re-used much of the original roof (steel trusses and framing) and most of the existing cinder block walls. We also salvaged a truckload of the 2x6s and 2x8s from the original building for reuse in nonstructural framing and blocking in the walls (reducing the need for new timber).

The manufacturing, transportation, and resource extraction of wood materials emits less carbon pollution when compared its steel and concrete counterparts, and it keeps carbon sequestered over the building’s lifetime.

The wood flooring we selected is reclaimed wood milled in the Pacific Northwest. The majority of the building’s structure is comprised of wood framing, including FSC-certified mass timber glulam beams, cross-laminated timber (CLT) panels for the roof, and structural wood posts. By using CLT panels, we reduced material waste and saved time because the installation is a lot faster than alternative materials.

The tile installed throughout the bathrooms has 40% recycled contents and the gypsum drywall is designed to weigh less, also including recycled materials.

PaperStone countertops are certified by the Forest Stewardship Council® (FSC®). All of the paper is post-consumer recycled paper and old cardboard container paper. Layers of this paper are pressed into “stone” using resin made from industrial by-products that would otherwise go into the waste stream and have been specially designed to produce a hardwood-like, highly workable, non-brittle composite panel.

The carpet tiles we selected from Interface are third-party registered as “carbon neutral” through ISO-recognized carbon offsets. One of the carpet tiles is 70% recycled and another is made from bio-based materials. Both are recyclable at the end of product life.